|

Money talks in the new Freelander 2, confidently claimed to outstrip rivals. Review and a little nostalgia by Anthony Howard...

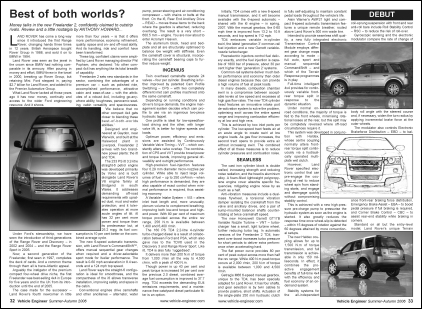

LAND ROVER has come a long way since it introduced the first Range Rover, changing hands three times in 12 years. British Aerospace bought Rover Group in 1988, and sold it on to BMW in 1994. Land Rover was seen as the jewel in the crown since BMW had nothing comparable in its armoury. After pouring in money and effort, BMW threw in the towel in 2000, breaking up Rover Group, but retaining Mini. Ford stepped in, paying $2.7 billion for Land Rover, and added it to the Premier Automotive Group. What Land Rover lacked all those years ago it has now: money, continuity and access to the wider Ford engineering resource. And it shows. Under Ford’s stewardship, we have seen the introduction of third-generations of the Range Rover and Discovery – in 2002 and 2004 – and the Range Rover Sport in 2005. Now, a second generation of the Freelander, first seen in 1997, completes the deck of cards. And a common theme through them all is trans-Atlantic appeal. Arguably the instigator of the premium compact four-wheel drive niche, the first Freelander was best-selling 4x4 in Europe for five years and in the UK from its introduction until the end of 2005. The case made for the successor – Land Rover’s fourth newcomer in little more than four years – is that it offers more: performance, economy, refinement, quality, space and on- and off-road ability. And its handling, ride and comfort have been transformed. These big, confident claims were amplified by Land Rover managing director Phil Popham, who declared: ‘No other compact 4x4 has anything like its total breadth of capability. ‘Freelander 2 sets new standards in the sector, combining the advantages of a premium car – such as polished ride, accomplished performance, attractive cabin and ease-of-use – with the attributes of a robust 4x4, including go-anywhere ability, toughness, panoramic seating, cabin versatility and spaciousness. ‘We believe that no other compact 4x4 gets closer to blending these best-of-both-worlds abilities.’ Designed and engineered at Gaydon, near Warwick, and built at the Halewood plant in Liverpool, Freelander 2 arrives with two brand-new power plants: the i6 and TD4. The 233 PS i6 3.2-litre straight-6 petrol engine was developed primarily by Volvo and is built alongside Land Rover’s V8 engine family at Bridgend in south Wales. It addresses demanding off-road requirements with uprated dust, mud and water protection, and it tolerates operation at more acute angles of tilt. i6 has 32 per cent more power and torque than its predecessor but, at 25.2 mpg, its fuel consumption is 10 per cent better on the combined average cycle. The new 6-speed automatic transmission, with Land Rover’s CommandShift™, offers manual sequential gear changes when required and a driver-selectable sport mode for livelier performance. The result is 0-60 mph acceleration in 8.4 seconds and a 124 mph top speed. Land Rover says the straight-6 configuration is ideal for smoothness, and the compactness of the i6 allows transverse installation, improving safety and space in the cabin. Conventional engines drive camshafts and other ancillaries – alternator, water pump, power steering and air conditioning compressor – with chains or belts at the front. On the i6, Rear End Ancillary Drive – READ – moves these items to the back where the gearbox is attached, reducing overhang. The result is a very short – 600.5 mm – engine. You are now about to enter Acronym Heaven. The aluminium block, head and bedplate and all are structurally optimised to balance low weight with stiffness. Even the camshaft cover is structural, incorporating the camshaft bearing caps to further reduce weight. ingenious Twin overhead camshafts operate 24 valves – four per cylinder. Breathing is further improved by patented Cam Profile Switching – CPS – with two completely different inlet cam profiles machined onto the same camshaft. Depending on running conditions and driver’s torque demands, the engine management system decides which cam profile to use via an ingenious two-piece hydraulic tappet. One profile is ideal for low-speed/low-load driving and the other, with longer valve lift, is better for higher speeds and loads. Optimum power, efficiency and emissions are assisted by Continuously Variable Valve Timing – VVT – which constantly alters valve overlap. The combination of CPS and VVT provide broad power and torque bands, improving general driveability and outright performance. High-precision fuel-injection features four 0.29 mm diameter micro-nozzles per cylinder. While able to inject large volumes of fuel – up to 250 cm3/min – when high performance is demanded, they are also capable of exact control when minimal performance is required, thus assisting economy. A Variable Intake System – VIS – alters inlet tract length and, more unusually, plenum volume to complement breathing, improving both low-end torque and high-end power. With 80 per cent of maximum torque provided across the entire rev range, 256 N.m is available between 1,400 and 6,400 r/min. The 160 PS TD4 2.2-litre 4-cylinder turbo-charged diesel is a result of collaboration between Ford and PSA, which also gave rise to the TDV6 used in the Discovery 3 and Range Rover Sport. Like i6, TD4 is also fully ‘ruggedised’. It delivers more than 200 N.m of torque from 1,000 r/min all the way to 4,500 r/min, with a peak of 400 N.m. Though power is up 43 per cent and peak torque is increased 54 per cent over the previous 2.0 diesel, combined average fuel consumption is improved to 37.7 mpg. TD4 exceeds the demanding EU4 emissions requirements, and a maintenance-free catalysed diesel particulate filter is an option. Initially, TD4 comes with a new 6-speed manual transmission, and it will become available with the 6-speed automatic – shared with the i6 engine – in spring, 2007. With the manual gearbox, the 0-60 mph time is improved from 13.2 to 10.9 seconds, and top speed is 112 mph. TD4 embraces variable in-cylinder swirl, the latest ‘generation 3’ common-rail fuel injection and a new Garrett variable-nozzle turbocharger. Piezoelectric injectors control fuel delivery exactly, and the fuel injection is capable of 1800 bar of pressure, about 30 per cent higher than ‘generation 2’ systems. Common-rail systems deliver much better performance and economy than older diesel engines because they can provide a high volume of fuel at peak loads. In many diesels, combustion chamber swirl is a compromise between acceptable levels at low speed and excesses at high gas flow rates. The new TD4 cylinder head features an innovative intake port de-activation system to solve the problem, optimising swirl across the entire speed range and improving combustion efficiency at low and high revs. This is achieved by two inlet ports per cylinder. The low-speed tract feeds air at an acute angle to create swirl at low engine loads. As gas flow increases, the second tract opens to provide extra air without increasing swirl. The combined effect of all these measures is to reduce cylinder pressures and combustion noise. seamless The cast iron cylinder block is double walled, increasing strength and reducing noise radiation, and the head is aluminium alloy. A foam-filled lightweight polypropylene engine cover absorbs specific frequencies, mitigating engine noise by as much as a half. Anti-vibration measures include a dual-mass flywheel, a torsional vibration damper isolating the crankshaft from the valve and ancillary drives, and a pair of sump-mounted balancer shafts counter-rotating at twice crankshaft speed. The new Honeywell Garrett GT17B Variable Nozzle Turbine – VNT – turbo-charger has a small, light turbine wheel, further reducing turbo lag. In automatic versions of the Freelander 2 TD4, transient over-boost increases turbo pressure for short periods to deliver extra performance when accelerating hard. The flat power curve provides 80 per cent of peak output across more than half the rev range. While 400 N.m peak torque occurs at 2,000 r/min, 200 N.m of torque is available between 1,000 and 4,500 r/min. Getrag’s M66 6-speed manual gearbox, unique to the TD4, has been specially adapted for Land Rover. It has four shafts, and gear selection is by twin cables to provide positive, short shifts. Actuation of the single-plate 250 mm hydraulic clutch is fully self-adjusting to maintain constant pedal loads throughout the vehicle’s life. Aisin Warner’s AWF21 light and compact 6-speed automatic transmission features a unique remote breather, routed above Land Rover’s 500 mm wade line. Intended to provide seamless shift quality, a new fully integrated electronic Transmission Control Module employs different gear change maps according to mode – full auto, sport and manual sequential CommandShift – and which of the Terrain Response programmes is in play. Full-time intelligent 4x4 provides for continuously variable front-rear torque split in response to the dynamic situation. Under normal on-road conditions, the majority of torque is fed to the front wheels, minimising rotational losses at the rear, but this split may be completely reversed where off-road circumstances require it. This system was developed in conjunction with Haldex, whose centre coupling normally alters front-rear torque split continuously via a hydraulically operated multi-plate wet clutch. However, Land Rover specified electronic control that can pre-engage the coupling at rest to reduce wheel spin from standing starts, and engage and disengage quickly without compromising stability control. This is achieved with a new high-pressure pre-charge pump to pressurise the hydraulic system as soon as the engine is started. It also greatly reduces the response time once wheel-slip is detected – within 15 degrees of rotation against the 60 degrees attained by more conventional setups. The new Haldex coupling allows for up to 1,500 N.m of torque transmission, and full transmission is achievable in only 150 milliseconds. In effect, it combines the pro-active engagement benefits of full-time 4x4 with the efficiency and fuel economy of an on-demand system.

Stability systems for the all-independent coil-sprung suspension with front and rear anti-roll bars include Roll Stability Control – RSC – to reduce the risk of roll-over. Gyroscopic sensing and the electronic modulator compare the rate of change of body roll angle with the steered course and, if necessary, widen the turn radius by applying incremental brake force at the outer wheels. The modulator also controls Electronic Brakeforce Distribution – EBD – to balance front-rear braking force distribution, Emergency Brake Assist – EBA – to boost pedal pressure if full braking is required, and Corner Brake Control – CBC – to assist rear-end stability while braking in corners. Standard on all but the entry-level model, Land Rover’s unique Terrain Response™ is at work continuously. Linked to the modulator, it adapts the behaviour of the engine, gearbox, centre coupling and chassis to suit the terrain with a choice of four settings – general driving, grass/gravel/snow, mud/ruts, or sand – selectable via a rotary control. It also manages a variety of stability and traction aids:

Stopping power comparable to that of a good compact sports saloon is claimed for Freelander 2’s four-channel anti-lock brakes with large vented front and rear brake discs. The front discs – 316 mm on the petrol model and 300 mm on the diesel – are ‘reverse vented’, drawing cool air in over the central bell and venting out of the rim to improve thermal stability under severe braking. The 302 mm rear discs incorporate drum-in-disc handbrakes with two shoes per wheel for better hill-hold performance. Wheels are all low-pressure die-cast aluminium with wider than normal rims, and range from 16 to 19 inches in diameter. All-terrain rated tyres are sized from 215/75R16 on the diesel only to an optional 235/55R19. Adjustable for reach and rake, the steering operates with 2.6 turns lock-to-lock, and the rack is rigidly mounted to the front sub-frame, improving lateral stiffness. Supple long-travel suspension with large-diameter gas damper struts and rubber-mounted front and rear sub-frames assist on-road ride comfort while 210 mm – minimum – ground clearance facilitates rough off-road work and wading. Freelander 2’s fresh exterior and interior design lines it up with the style of the rest of the Land Rover range. ‘We purposely kept strong cues from the original Freelander, such as the clamshell bonnet, stepped roof and the basic form,’ said design director Geoff Upex, due to retire at the end of 2006 after 23 years with the company. ‘But the overall look is new and much more contemporary. The design is chiselled, geometric and simple – it looks like it’s hewn from the solid. ‘We have kept a close design relationship with the new Discovery 3 and Range Rover Sport, but interpreted the design language to suit the requirements of customers for a more compact 4x4. Freelander 2 is a fresh and contemporary design, with chunky good looks and sporty energy. Though the genes of the highly successful original Freelander are still clearly recognisable, the new model looks more premium and more grown-up, without losing its sense of fun.’ According to Upex, 4x4s typically appear more geometric, more aggressive and harder-edged. Cars tend to be more organic – and friendlier – in form. So the Freelander 2 mixes strong geometric shapes and flowing, car-like softness. Its 5-door monocoque body is 50 mm longer, 109 mm wider and 32 mm higher than Freelander 1, and has more head, shoulder and leg room, front and rear. SAFETY ‘Stadium seating’ affords rear passengers a better view of the outside world by placing them slightly higher than front occupants, and boot space with rear seats up is increased 38 per cent from 546 to 755 litres. Volume with rear seats folded forward is up 27 per cent to 1,670 litres. The basis for sound ride, handling and refinement, the monocoque – with static stiffness of more than 28,000 N.m/degree – is almost twice as rigid as some competitors. Ultra-high-strength DP600 dual-phase steel, which requires special pressing, is used more extensively than in any previous Land Rover – for the door beams, A-posts, lower sills, cant rails, front side-members and scuttle to help provide a weight-efficient safety cell. In addition, many of the components bolted on during final assembly also help improve structural integrity. A double bulkhead in the engine bay improves power train isolation and provides a clean area for components such as the ABS modulator, brake servo and wiper system. Thanks to 100 per cent use of double-sided zinc-coated steel panels, Freelander 2 comes with an unlimited-mileage, three-year paint-surface warranty and six-year anti-corrosion warranty. The variety of seat fabrics and colour ways on offer includes leather in top-of-the-range models. ‘The whole interior has moved significantly up-market,’ Geoff Upex pointed out. ‘Quality and craftsmanship are improved, with higher-specification materials used throughout the cabin – it feels like that of a premium saloon car. ‘It’s comfortable, attractive, well equipped and spacious. There is a real sense of space. You can stretch out and relax, and it makes the whole ambience so much more enjoyable.’ Upex and lead interior designer Martin Buffery decided early on that the new interior should be more elegant and simpler than its predecessor, and they describe the result as ‘strong but not intimidating’. All models have front seat belt pre-tensioners and seven airbags. Front air bags provide the driver and passenger with head and chest protection, and they also have the benefit of side airbags. An inflatable knee bolster protects the driver against leg injury from the steering column. Full-length curtain airbags in the roof side structure help prevent head injuries and roll-over ejection of front and rear occupants. The long list of features includes keyless starter button, rain-sensing wipers, front and rear parking distance control, a double panoramic sunroof and air-conditioning, standard on all variants. Also available are full-colour touch-screen DVD satellite navigation and a choice of top-level audio systems, including DAB digital radio and 12-speaker Dolby™ Prologic IIx Surround Sound with fibre-optic interconnects. Freelander 2 is also available with High Intensity Discharge – HID – projector lights with bulbs containing a mixture of noble gases, including xenon, that produce a crisp blue-white ‘daylight’ spectrum. Though creating 200 per cent more light than halogen units, they consume half as much electricity and last 10 times longer. The HID system includes power wash and automatic levelling, and optional Adaptive Front Lighting – AFS – swivels the headlights in the direction of travel. UK prices for the new Freelander will be in the £22,000-£30,000+ range l |

|

DURING a visit to Solihull in 1970, I was driven round the test track in the new Range Rover – a handsome and innovative beast devised by Spen King and his team, it was to endure for 26 years. But, at the time of its introduction, most people’s experience of 4x4s was limited to utilitarian boneshakers such as cart-sprung Land Rovers and the odd Jeep, laden with Jack Russell terriers or sheep and sacks of grain. After a couple of laps on the tarmac, my host turned smartly off across a field. Pretty startling, especially because if anything he drove even faster. Amazingly, the suspension simply mopped up the ruts, and the device didn’t fall over. Little did I dream that, 10 years later, I would drive a Range Rover in my first Paris-Dakar Rally – with my old mate Anne Hope, publisher of VE. ‘We’ll never be the same again,’ she said. Thus began an all-consuming, expensive obsession that continued into the 1990s. If I learnt anything amid the dunes and wide horizons of the Sahara, it was just how many adrenalin-fuelled liberties one could take with a Range Rover – attaining myriad crazy angles at speed, without parking the thing on its roof. Much the hardest part was marshalling the necessary hardware and money – these days, they call this sponsorship marketing. Getting the car built to any kind of standard in double-quick time was a bit easier. And competing in the rally itself seemed like kid’s stuff by comparison. These efforts relied hugely on the goodwill and behind-the-scenes support of key people with the gumption to see the point. In turn, their capacity to abet these ventures mirrored the ups and downs of Land Rover Ltd, then a division of BL. The task became progressively more difficult as the company began its cultural shift towards shag-pile carpets and walnut door cappings, appealing more to urban buyers, an astonishing number of whom apparently seemed unaware they had four-wheel drive. So associations with mud, sand, dust and greasy motor sporting hooligans came to be disdained as outré. It was a bumpy ride. Say no more l |

|

IN addition to unveiling the new Freelander 2 at ExCel, Land Rover announced its CO2 Offset Programme to help balance emissions from its manufacturing operations and customer vehicles. A pilot scheme run by Climate Care, it will finance alternative energy projects, such as wind and solar power, energy efficiency and technology change. It will run from September, 2006, to the end of 2008, and is expected to offset 2 million tonnes of CO2. This will take some explaining. Another initiative is the Land_e Technology Concept that showcases the e-Terrain System – an ensemble of innovations intended to reduce fuel consumption and emissions by as much as one-third, while also improving the capabilities of the company’s SUVs. Among these pointers to the future: 1: A 6-cylinder petrol engine capable of running on any blend of bio-ethanol and petrol up to E85. This incorporates a Belt-Integrated Starter-Generator – B-ISG – or micro-hybrid system, in place of the conventional alternator, yet still driven by the normal ancillary belt. 2: Land Rover’s unique integrated Electric Rear Axle Drive – ERAD – provides electric drive alone at low speed, and is claimed to improve 4x4 ability on difficult terrain. ERAD enhances off-road performance by augmenting rather than replacing the mechanical drive. Land Rover says this is an improvement on some competitors’ hybrid technologies, which employ electric drive to the rear axle only, significantly reducing off-road potential. Low-speed torque from ERAD offers a number of advantages on-road. Among them are electric-powered ‘traffic creep’ and low-speed acceleration to 20 mph – without restarting the engine l |

|

Copyright © by Anthony Howard for Vehicle Engineer |